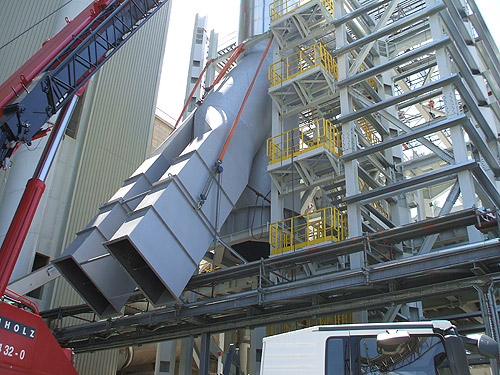

Production of steel components for the heat exchanger in Wössingen, Germany: In an 11-month construction period, 1900 tons of steel and around 800 tons of processing equipment were engineered and pre-assembled in Dinklage. The transport and final assembly were also designed and implemented by Hilgefort, a single-source supplier.

The order also included comprehensive detailed engineering. The necessary process equipment in the approximately 112 m high tower, such as calciners, tertiary air ducts, combustion and mixing chambers and five cyclone separators, was built turnkey by Hilgefort.

In addition, the company produced and assembled the steelwork, including stairs, scaffolding and 500 m long conveyor. A rotary kiln was partially reconditioned.